How to Align the Right Supply Chain App With Your Needs

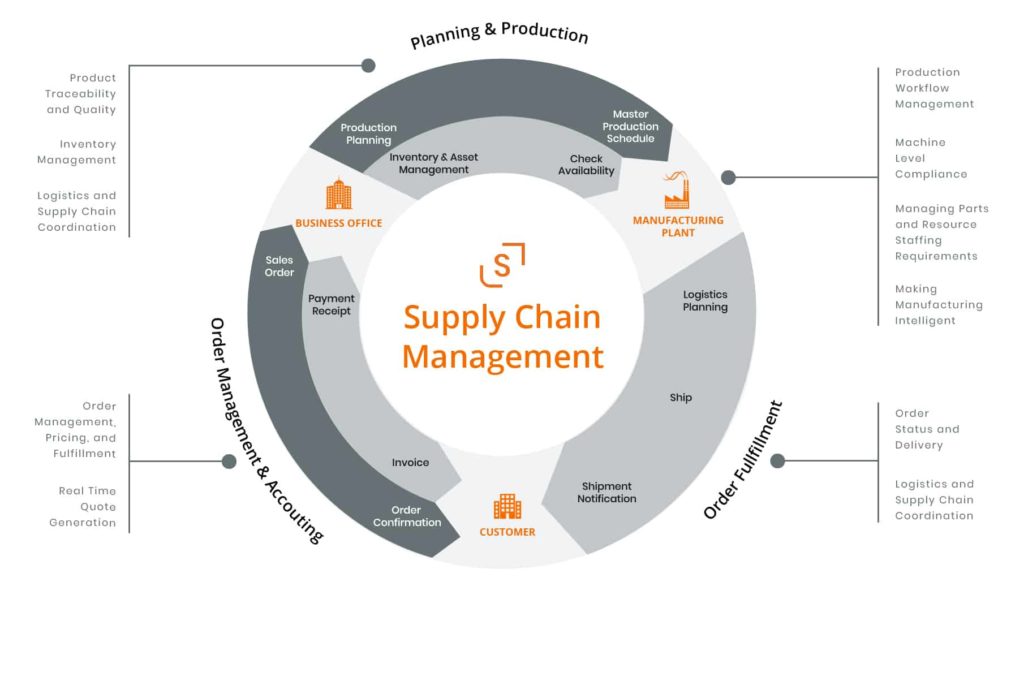

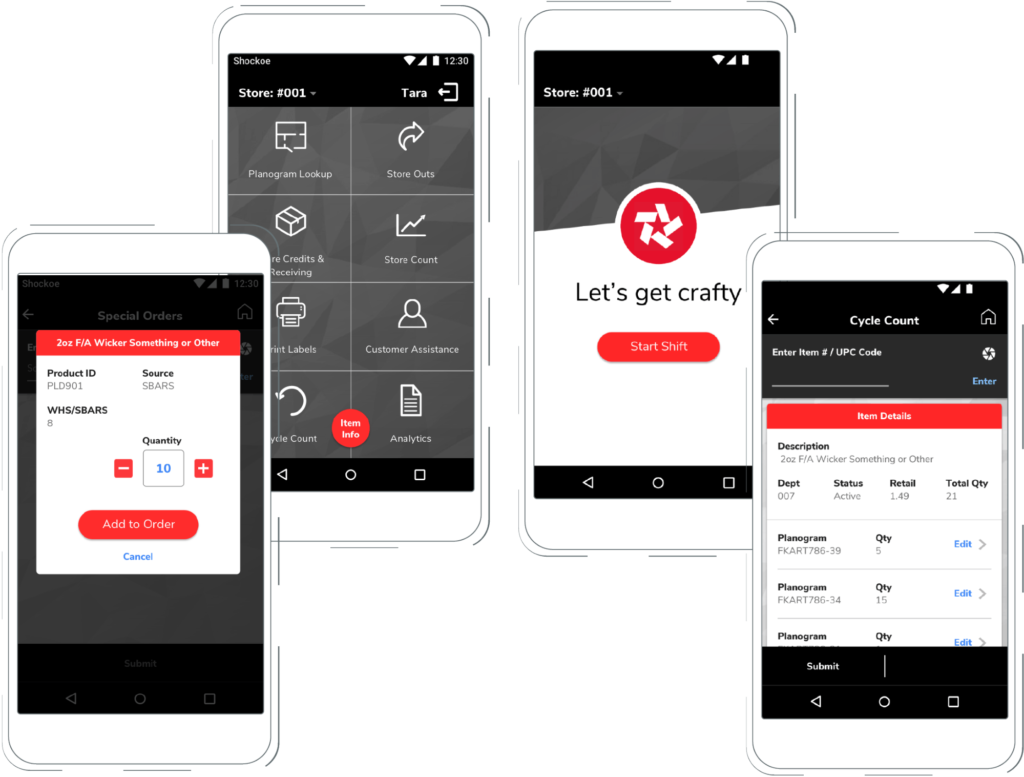

Prioritizing the strategic importance of technology that supports your supply chain is essential. Mobile Solutions are an integral and expanding component of the technology landscape that support all steps of the manufacturing process. Organizations that have mobilized solutions such as enterprise resource planning (ERP), enterprise asset management (EAM) or field service management (FSM), warehouse management system (WMS), Inventory Management System (IMS), etc. are more prepared tackle the overall digital transformation. By 2018, mobile has served as the key to unlocking the “supply chain digital transformation.” Shockoe is creating supply chain apps that are designed to support new production strategies, reduce time to manage and log resource and production activity, bring greater accuracy to tracking and analyzing data, and support the automation of production centers. Within the supply chain, more specifically warehouse management, manufacturing, and distribution, there are several opportunities for leveraging mobile in the workforce. In working with our clients, we believe the list below is the starting point for mobile solutions. These supply chain app options are aimed at supporting the overall manufacturing and sales process through an ecosystem of inventory apps, customer-facing apps, and order fulfillment apps.

Mobile Apps to Consider by Point in the Supply Chain

Planning & Production Apps

-

- Managing parts and resource staffing requirements

-

- Production workflow management

-

- Inventory and asset management apps

-

- Logistics and supply chain coordination

- Logistics and supply chain coordination

Production Planning Apps are not only used for the manufacturing business, but also across the entire supply chain. Production planning apps allow users to manage the overall process in three primary ways:

-

- Augment your Production Planning System: A Production planning solution is only the first step in transforming the planning process from a manual process based on spreadsheets to one based on integrated sales history-based forecasting and confirmed sales orders/release schedules, Mobile Apps allow your team to make real-time decisions based on information obtained through a Mobile App

-

- Managed Strained Resources: What happens when you find out that there will be a 10 percent increase in demand next month but you have no idea if you’ve got the labor, warehouse space, or raw materials to fill these extra orders? What happens if your demand shifts mid-cycle? Master scheduling can be controlled via a computer, but why not get the insights to do it on your mobile app.

- Disconnected Plant Floor: Errors mean waste, unhappy customers, and non-compliance. As your business grows, mobile becomes the only way to ensure your team can “be there”, on the plant floor, to know what’s going on at any given moment. Operators and Managers need to focus on the task at hand, not on managing issues. Mobile Apps give Managers and Operators a complete view of the manufacturing operation that is available to the entire organization but on the shop floor.

Order Management & Accounting Apps

Mobile Apps that fall into this category include:

-

- Order management apps, pricing, and fulfillment

-

- Real-time quote generation

There are two types of helpful applications that support the order management and accounting process. Order Management and Fulfillment Apps will support users with:

-

- Two-way transmission of orders, inventory, shipping, & Invoices

-

- Track process of fulfillment orders real-time and close the fulfillment loop

-

- Enable shippers to track order progress

Real-time quote generation also has some great benefits.

Order Fulfillment and Compliance Apps

Mobile Apps that fall into this category include:

-

- Order status and delivery

-

- Product traceability and quality

-

- Logistics and supply chain apps

-

- Machine level compliance and intelligence

Much like the production & planning stage, order fulfillment falls apart due to inefficient operations, a lack of integration, and a lack of inventory knowledge. Mobile Apps can relieve the following key pain points experienced:

-

- Automate Entry for Order Fulfillment: We see our clients continue to use a manual process for order entry as their go-to option. This leads to all kinds of inaccuracies in the order, from the items needed to fulfill it, to where it is being sent. Mobile apps can equip operators with the equipment necessary to eliminate manual entry errors on things like product SKUs, quantity, and shipping addresses

-

- Resolve Inventory Inaccuracies & Inefficiencies: Having the right inventory is only half the challenge, operators need to know where it is and how to get to it. Mobile is not the only solution for this, there are two things your team needs to do, (1) Make sure to have a floor layout that makes inventory visible first, from a Mobile Perspective, track inventory as it enters and leaves the warehouse in a centralized system, mobile apps enable employees to do this quickly and efficiently, real-time.

-

- Team Communication in Fulfillment: Miscommunication can cause shipping delays just as much as a disorganized warehouse. If the entire team isn’t on the same page and has no direct access to managers, too much time is spent “chasing” down the right person. As a warehouse manager, you may have all the vendor information you need – but that won’t help your team unless you communicate the information that they need, with a supply chain app in hands, your team can be in constant communication.

When prioritizing and considering mobile supply chain solutions to support the manufacturing, administrative, and customer engagement process, Shockoe suggests using three key metrics to prioritize supply chain app development versus alternative mobile applications or the overall technology portfolio.

Reduce Manual Labor and Increase Productivity

Delivering a successful customer experience and subsequently driving more revenue requires mobile leadership and prioritization activities to go beyond the building of apps for customer-facing roles (i.e. Work Order Management or Sales). Back-office workers, technicians, and managers need mobile access to enterprise systems to better perform their jobs and service customers more efficiently. Think about creating a better mobile experience by integrating with ERP or WMS systems for, example, giving employees more freedom to do their jobs wherever and whenever. Critical features for a mobile supply chain functions are scheduling, measuring, and dispatching the workforce. Leveraging the mobile context for such, will allow organizations to accurately measure and improve the productivity of each individual. Which finally in turn will allow organizations to accurately measure and improve the productivity of each individual. Going beyond technology and mobility, an app that enables the workforce can also collect data essential to future planning. The organization can better analyze how much more work it can take on and whether there are enough people to support the forecasted workload.

Revenue

Historically speaking, revenue was only accounted for from a customer standpoint. Integrating new technologies to create a mobile supply chain allows monitoring and assessing revenue percentage at the process level. Being able to quickly obtain the percentage of revenue contribution at each step in the order to cash process is valuable information for real-time decision making and forecasting. Mobile solutions can track performance at each step which gives both locations with context. These values help indicate whether a measured process is underperforming or contributing significantly to the overall revenue. Whether it’s an investment in an asset management app or an inventory management app, whatever it is, a more granular overview of information through your processes can help target your areas of growth, need, and reward in the supply chain.

Automation

Automation, IOT, and Machine Learning are popular terms. What manufacturing companies really need to worry about and set goals for is the extent of the automation planned and how these emerging technologies can help. Once the business understands its goal, mobile solutions can embrace IoT devices to enable the desired automation. Allowing employees to monitor automated processes on mobile devices can decrease error rates, speed fulfillment processes, and ultimately settle cash faster. The continuing development and availability of newer and better technology imply that processes can be made to work faster, repetitive work can be automated, FTEs can be reduced, operations can be systemized, and customer handling can be improved. Tackling automation, IOT, or machine learning require a set of tough decisions:

-

- To what level will I automate the process?

-

- What aspects of the process will I automate?

-

- What tools will my employees use to monitor and be alerted of the process?

The mobile supply chain is the next era of communication, collaboration, and responsiveness to the customer, driven by the ability to meet ever-more-stringent deadlines and delivery dates. Start from your key challenges and business objectives, use the right metrics to prioritize, and plan your journey for successful implementation of mobile, IoT and emerging technologies. Shockoe works in the supply chain to prioritize manufacturing apps and technology that support essential business processes. Mobile Solutions are at the forefront of all digital transformations and can support all areas of the manufacturing process. The right mobile app can help manage several areas of the manufacturing process and beyond.

Sign up for the Shockoe newsletter and we’ll keep you updated with the latest blogs, podcasts, and events focused on emerging mobile trends.

Check out our other blogs and ideas

How to Align the Right Supply Chain App With Your Needs

blog

Blog Post

Written by

Alex Otanéz

Prioritizing the strategic importance of technology that supports your supply chain is essential. Mobile Solutions are an integral and expanding component of the technology landscape that support all steps of the manufacturing process.

We capture a range of fidelity content, all pre-planned to make the most channel-right assets.

Organizations that have mobilized solutions such as enterprise resource planning (ERP), enterprise asset management (EAM) or field service management (FSM), warehouse management system (WMS), Inventory Management System (IMS), etc. are more prepared tackle the overall digital transformation.

By 2018, mobile has served as the key to unlocking the “supply chain digital transformation.” Shockoe is creating supply chain apps that are designed to support new production strategies, reduce time to manage and log resource and production activity, bring greater accuracy to tracking and analyzing data, and support the automation of production centers.

Within the supply chain, more specifically warehouse management, manufacturing, and distribution, there are several opportunities for leveraging mobile in the workforce. In working with our clients, we believe the list below is the starting point for mobile solutions. These supply chain app options are aimed at supporting the overall manufacturing and sales process through an ecosystem of inventory apps, customer-facing apps, and order fulfillment apps.

Mobile Apps to Consider by Point in the Supply Chain

Planning & Production Apps

- Managing parts and resource staffing requirements

- Production workflow management

- Inventory and asset management apps

- Logistics and supply chain coordination

Production Planning Apps are not only used for the manufacturing business, but also across the entire supply chain. Production planning apps allow users to manage the overall process in three primary ways:

1 - Augment your Production Planning System: A Production planning solution is only the first step in transforming the planning process from a manual process based on spreadsheets to one based on integrated sales history-based forecasting and confirmed sales orders/release schedules, Mobile Apps allow your team to make real-time decisions based on information obtained through a Mobile App

2 - Managed Strained Resources: What happens when you find out that there will be a 10 percent increase in demand next month but you have no idea if you’ve got the labor, warehouse space, or raw materials to fill these extra orders? What happens if your demand shifts mid-cycle? Master scheduling can be controlled via a computer, but why not get the insights to do it on your mobile app.

3 - Disconnected Plant Floor: Errors mean waste, unhappy customers, and non-compliance. As your business grows, mobile becomes the only way to ensure your team can “be there”, on the plant floor, to know what’s going on at any given moment. Operators and Managers need to focus on the task at hand, not on managing issues. Mobile Apps give Managers and Operators a complete view of the manufacturing operation that is available to the entire organization but on the shop floor.

Order Management & Accounting Apps

Mobile Apps that fall into this category include:

- Order management apps, pricing, and fulfillment

- Real-time quote generation

There are two types of helpful applications that support the order management and accounting process. Order Management and Fulfillment Apps will support users with:

- Two-way transmission of orders, inventory, shipping, & Invoices

- Track process of fulfillment orders real-time and close the fulfillment loop

- Real-time quote generation

Real-time quote generation also has some great benefits.

Order Fulfillment and Compliance Apps

Mobile Apps that fall into this category include:

- Order status and delivery

- Product traceability and quality

- Logistics and supply chain apps

- Machine level compliance and intelligence

Much like the production & planning stage, order fulfillment falls apart due to inefficient operations, a lack of integration, and a lack of inventory knowledge. Mobile Apps can relieve the following key pain points experienced:

1 - Automate Entry for Order Fulfillment: We see our clients continue to use a manual process for order entry as their go-to option. This leads to all kinds of inaccuracies in the order, from the items needed to fulfill it, to where it is being sent. Mobile apps can equip operators with the equipment necessary to eliminate manual entry errors on things like product SKUs, quantity, and shipping addresses

2 - Resolve Inventory Inaccuracies & Inefficiencies: Having the right inventory is only half the challenge, operators need to know where it is and how to get to it. Mobile is not the only solution for this, there are two things your team needs to do, (1) Make sure to have a floor layout that makes inventory visible first, from a Mobile Perspective, track inventory as it enters and leaves the warehouse in a centralized system, mobile apps enable employees to do this quickly and efficiently, real-time.

3 - Team Communication in Fulfillment: Miscommunication can cause shipping delays just as much as a disorganized warehouse. If the entire team isn’t on the same page and has no direct access to managers, too much time is spent “chasing” down the right person. As a warehouse manager, you may have all the vendor information you need – but that won’t help your team unless you communicate the information that they need, with a supply chain app in hands, your team can be in constant communication.

When prioritizing and considering mobile supply chain solutions to support the manufacturing, administrative, and customer engagement process, Shockoe suggests using three key metrics to prioritize supply chain app development versus alternative mobile applications or the overall technology portfolio.

Reduce Manual Labor and Increase Productivity

Delivering a successful customer experience and subsequently driving more revenue requires mobile leadership and prioritization activities to go beyond the building of apps for customer-facing roles (i.e. Work Order Management or Sales). Back-office workers, technicians, and managers need mobile access to enterprise systems to better perform their jobs and service customers more efficiently.

Think about creating a better mobile experience by integrating with ERP or WMS systems, for example, giving employees more freedom to do their jobs wherever and whenever. Critical features for a mobile supply chain functions are scheduling, measuring, and dispatching the workforce. Leveraging the mobile context for such, will allow organizations to accurately measure and improve the productivity of each individual. Which finally in turn will allow organizations to accurately measure and improve the productivity of each individual.

Going beyond technology and mobility, an app that enables the workforce can also collect data essential to future planning. The organization can better analyze how much more work it can take on and whether there are enough people to support the forecasted workload.

Revenue

Historically speaking, revenue was only accounted for from a customer standpoint. Integrating new technologies to create a mobile supply chain allows monitoring and assessing revenue percentage at the process level. Being able to quickly obtain the percentage of revenue contribution at each step in the order to cash process is valuable information for real-time decision making and forecasting. Mobile solutions can track performance at each step which gives both locations with context. These values help indicate whether a measured process is underperforming or contributing significantly to the overall revenue. Whether it’s an investment in an asset management app or an inventory management app, whatever it is, a more granular overview of information through your processes can help target your areas of growth, need, and reward in the supply chain.

Automation

Automation, IOT, and Machine Learning are popular terms. What manufacturing companies really need to worry about and set goals for is the extent of the automation planned and how these emerging technologies can help. Once the business understands its goal, mobile solutions can embrace IoT devices to enable the desired automation. Allowing employees to monitor automated processes on mobile devices can decrease error rates, speed fulfillment processes, and ultimately settle cash faster. The continuing development and availability of newer and better technology imply that processes can be made to work faster, repetitive work can be automated, FTEs can be reduced, operations can be systemized, and customer handling can be improved.

Tackling automation, IOT, or machine learning require a set of tough decisions:

- To what level will I automate the process?

- What aspects of the process will I automate?

- What tools will my employees use to monitor and be alerted of the process?

The mobile supply chain is the next era of communication, collaboration, and responsiveness to the customer, driven by the ability to meet ever-more-stringent deadlines and delivery dates. Start from your key challenges and business objectives, use the right metrics to prioritize, and plan your journey for successful implementation of mobile, IoT and emerging technologies.

Shockoe works in the supply chain to prioritize manufacturing apps and technology that support essential business processes. Mobile Solutions are at the forefront of all digital transformations and can support all areas of the manufacturing process. The right mobile app can help manage several areas of the manufacturing process and beyond.

We capture a range of fidelity content, all pre-planned to make the most channel-right assets.

Updating your consumer app is a great way to reengage your users, and with the right partner, you can create the necessary changes that leave you with a better app and happier customers. At Shockoe® we’ve worked in digital experiences for 12 years, creating the apps of the future today. When you’re ready to make a change contact our team to get started.

Reward Your Customers

Loyalty programs are a great way to reward app users for engaging with your company. But if your mobile app isn’t intuitive your loyalty program will get lost with the customers that matter. Winn-Dixie faced just that problem with a mobile app that left customers wanting more. Working quickly the Shockoe team launched an updated solution that moved the needle with shoppers and created a more intuitive and enjoyable shopping experience.

Updating your consumer app is a great way to reengage your users, and with the right partner, you can create the necessary changes that leave you with a better app and happier customers. At Shockoe® we’ve worked in digital experiences for 12 years, creating the apps of the future today. When you’re ready to make a change contact our team to get started.

Sign up for the Shockoe newsletter and we’ll keep you updated with the latest blogs, podcasts, and events focused on emerging mobile trends.